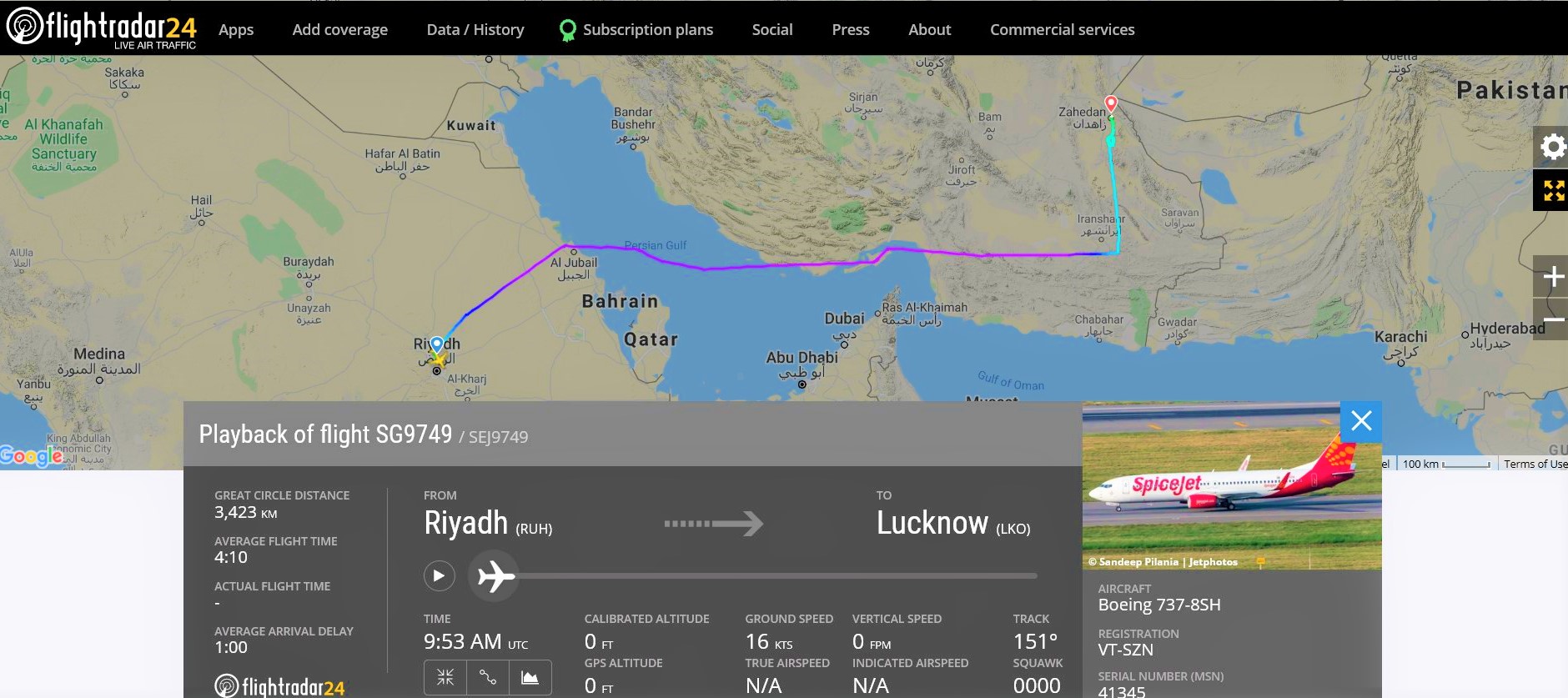

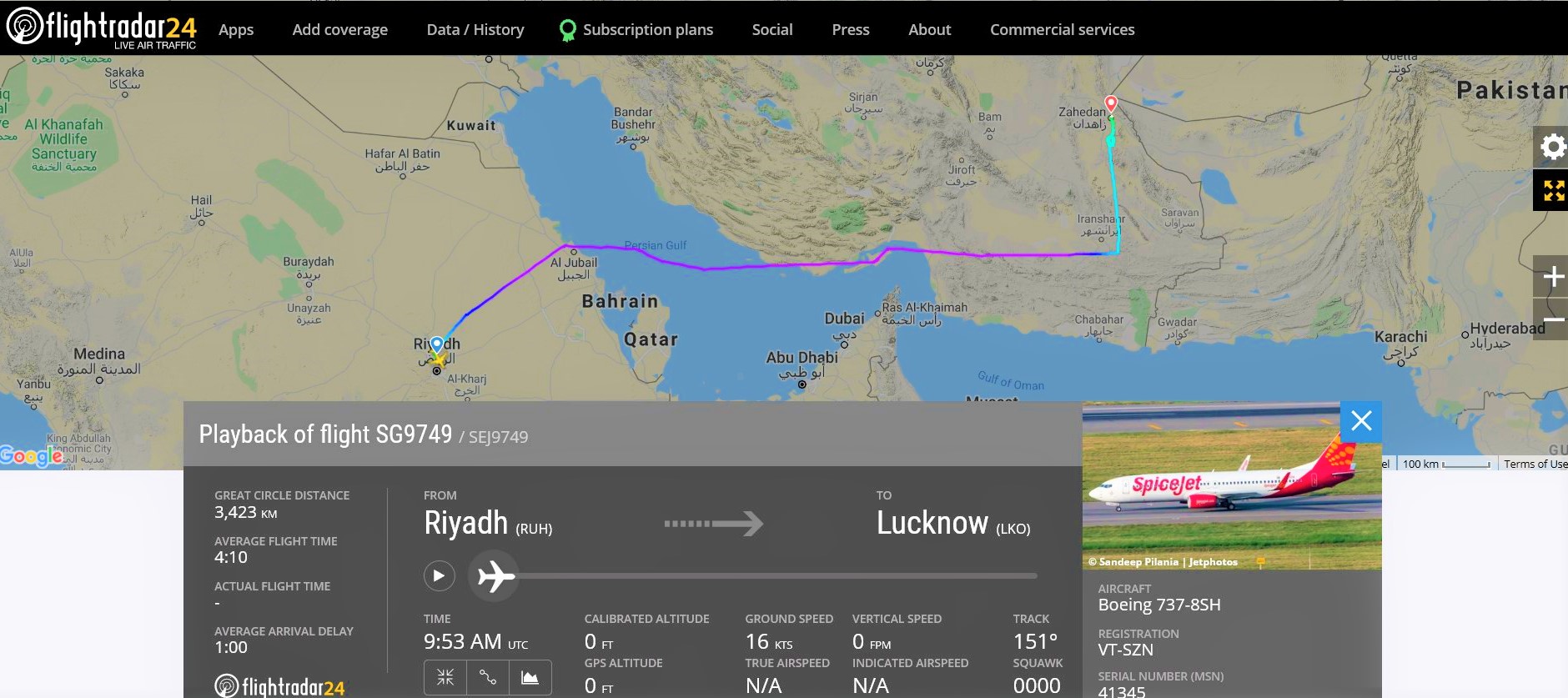

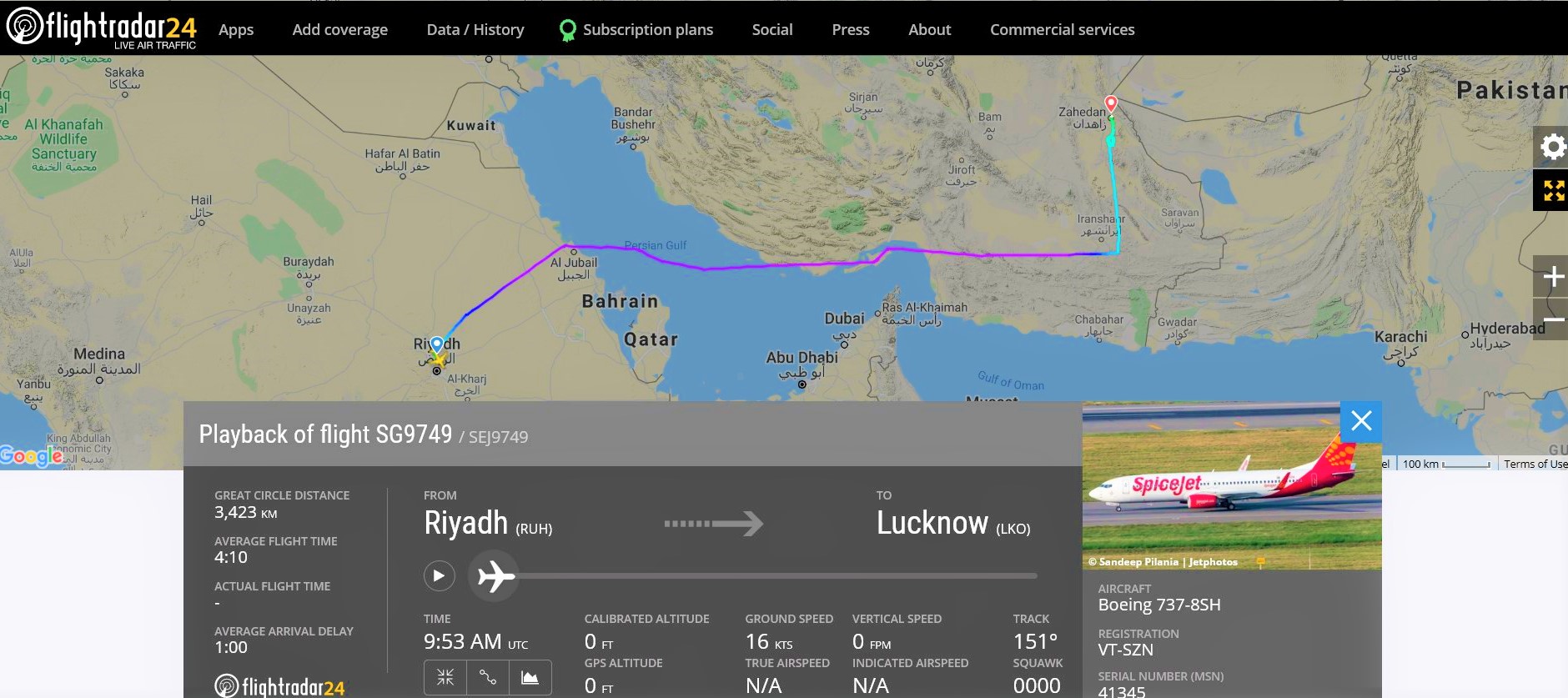

Indian budget carrier SpiceJet Boeing B737- 8SH aircraft was operating the flight SG -9749 ( Riyadh - Lucknow ) today . While cruising towards Lucknow, at Flight level 390 , the right windshield ( or First officer windshield) developed a crack .

The Cockpit decided to initiate a quick descent and asked ATC for a diversion to Zahedan (Iran) . After around 33 minutes of windshield crack incident at FL390 , the aircraft made a safe landing at Zahedan airport.

On further inspection on ground, it was found that the P2 side (or First officer windshield) windshield outer pane developed a crack, however , the inner pane of the winshield remained in good condition.

“On April 16, SpiceJet Boeing B737 aircraft was operating flight SG -9749 (Riyadh-Lucknow). During flight, P2 side windshield outer pane cracked (Inner pane intact),” the airline’s spokesperson mentioned in an announcement.

The aircraft rwas grounded at Zahedan (ZAH) for around 5 hours for the technical inspections , that include limitation check of cracks on winshield.

Though actual technical details for releasing the aircraft for flight are not known at the moment, aircraft departed for lucknow (India) after that.

Aircraft is maintaining a Lower altitude of FL270 at the moment and pressurization system did not encounter any further issues .

The airline reported the outer pane of the first officer's windshield cracked, the inner pane remained intact, the pressurization of the cabin remained normal.

Regd : VT-SZN

Type : B737-8SH

First Flight : 20/05/2016

Seriel Number : 41345 (LN:5931).

Engines : CFMI CFM56-7B26E

With a fail-safe design, windshield can carry upto 5,500 kg / 1Sqm of load in a pressurized flight.

1] One of the reason may be the quality of the windshield. An average windshield life is around 30,000FC. Substandard windshields age faster, Crack / crazing can initiate early . many times , OEMs are noticed to have changed Vendors for this reason.

2] At higher altitudes, the outside temp. is very low, windshields need to be heated . Again, uneven heating or short circuit can induce intensity change & break due to differential pressure of inside & outside the cabin.

3] Periodic checks needing windshield removal & installation can lead to an error / risk factor , if a wrong fastener is used or wroung torque / sequencing is used.

4] Possibility of an intruder /FOD. The windshield may be hit by something,such as a bird or hailstones at lower altitudes.

Always Refer Airplane flight manual / QRH for the actions !

But understanding is, If a crack appears , determine if it is on the inside or outside panel of glass. If it is the outside panel , verify in the QRH / or appropriate inflight manual before continuing further flight.

If it is the inside panel , begin to de-pressurize the aircraft & descend. Initiate safe Landing .

But, it is possible that, a cockpit crew fails to differentiate the crack orientation , in that case , the decision of the cockpit may take effect.