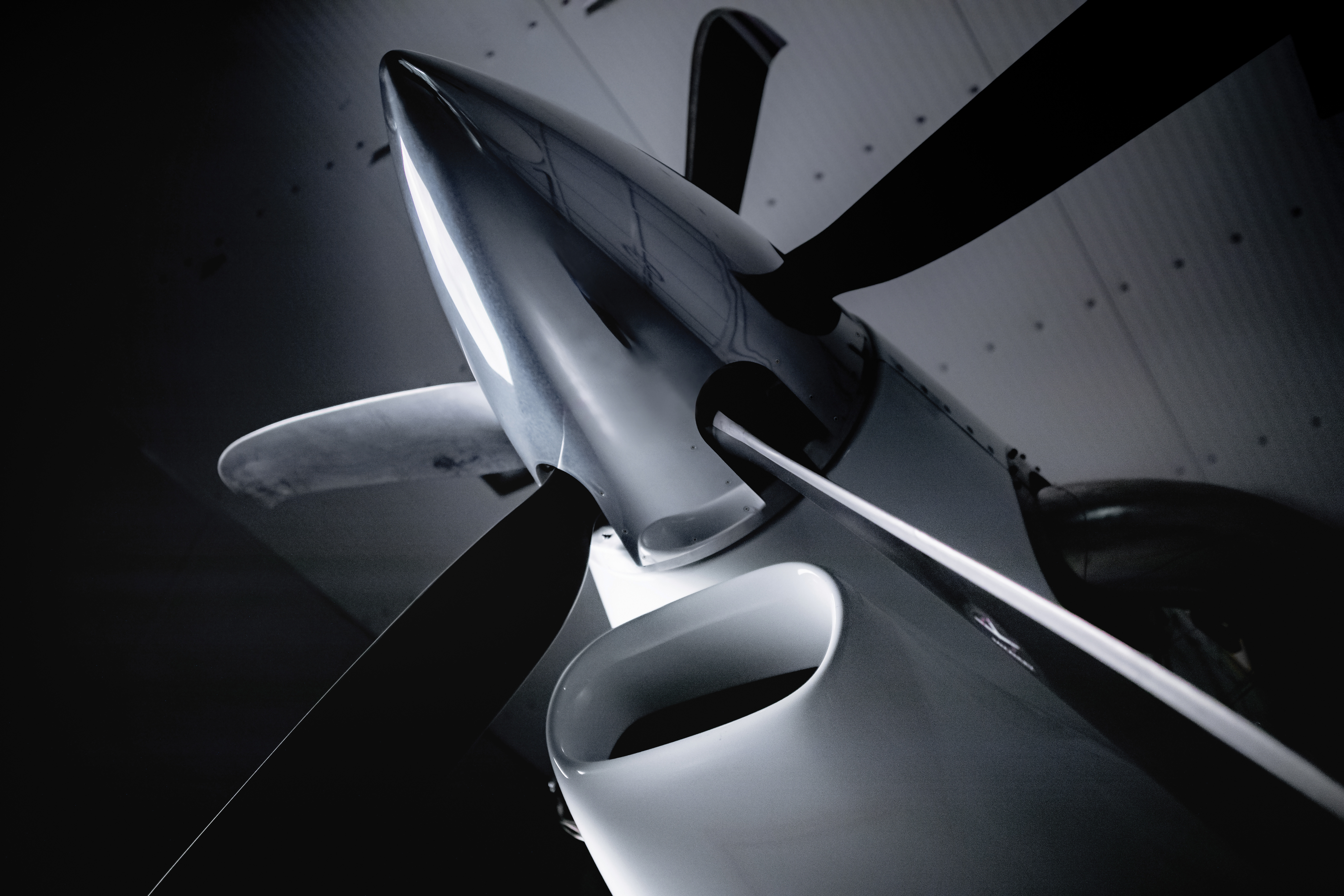

GE Aerospace has made an announcement that its Catalyst turboprop engine has been certified by the US Federal Aviation Administration (FAA). The FAR (Federal Aviation Regulation) Part 33 certification involved over 23 engines and more than 190 component tests.

Catalyst is the first, new centerline, clean-sheet advanced turboprop of the 21st century and the first turboprop engine to be certified to the latest standards, which include more than 20 significant new requirements.

The Catalyst engine is an original turboprop design to deliver a step change in performance and is the first turboprop in the aviation history made with 3D printed components.

GE Aviation Turboprop also delivered its first flightworthy engine to its launch customer, Textron Aviation, for the single-engine turboprop Beechcraft Denali.

The engine incorporates several groundbreaking features that set it apart from previous designs. With an overall pressure ratio of 16:1, the engine significantly reduces fuel consumption by 20% while delivering 10% more cruise power compared to similar engines in its class.

Riccardo Procacci, President and CEO, Propulsion and Additive Technologies at GE Aerospace said,

“The certification of the Catalyst engine is a significant milestone for our company and a proud moment for all our team members who have dedicated their efforts to the design, development, and testing of this brand-new European turboprop engine. We are now fully committed to supporting the production ramp-up of the engine towards the entry into service in support of our customers.”

During the certification process, the test engines completed more than 8,000 hours of operation demonstrating and meeting its key performance targets.

The Catalyst™ engine’s program was officially launched in 2015. The first run of the Catalyst™ engine on the Flying Test Bed began in December 2020.

Paul Corkery, Catalyst General Manager at Avio Aero said,

“Catalyst has been through a rigorous certification and testing process. We are pleased with the performance of the engine throughout its ground and flight test campaigns, and we remain fully focused on supporting Textron Aviation as they complete the certification process and prepare for entry into service of the Beechcraft Denali.”

The turboprop engine is equipped with a Full Authority Digital Engine Control (FADEC) system, which provides integrated propulsion control to enhance performance and reduce pilot workload. Additionally, the engine features variable stator vanes and cooled high-pressure turbine blades, contributing to its superior efficiency and overall reliability.

The engine is expected to bring a radical change to this segment, thanks to its industry-best 16:1 overall pressure ratio that enables up to 18% better fuel consumption and up to 10% higher cruise power, compared to competitors in the same engine class.

Catalyst introduces two stages of variable stator vanes, cooled high-pressure turbine blades, and features components made by using additive manufacturing.

About the Launch customer, Textron Aviation is aligning the Beechcraft Denali aircraft certification timing, expected in 2025, to the certification timeline for the Catalyst engine. The Denali is the first aircraft powered by the new, more efficient engine.

The Catalyst engine belongs to the GE Aerospace suite of next generation engines which are defining the Future of Flight. It was designed, developed, and manufactured at GE Aerospace sites in Europe, including Avio Aero in Italy, the Czech Republic, Poland, and Germany.

You may like to read....