AAIB Bulletin : AAIB-27411 Revealed that the Parked (London Heathrow Airport Stand 583) British Airways Boeing 787-8 Dreamliner (G-ZBJB) collapsed its Nose Landing gear (NLG) due to Non-compliance of a Certain OEM (Original Equipment Manufacturer /Boeing) Service Bulletin before the incident and wroung installation of the Nose Landing gear Lock Pin during a Fault trouble shooting sequence , on 18 June 2021 at 0651 hrs.

The aircraft was on stand being prepared for a cargo flight from London Heathrow to Frankfurt . A ground maintenance team was working to address three fault messages associated with the Nose Landing Gear (NLG) doors while the flight crew prepared the aircraft for the flight.

The Dispatch Deviation Guide confirmed that rectification of the defects could be deferred to a later date providing the landing gear was recycled to confirm the NLG doors functioned correctly.

To prevent the landing gear from retracting when up was selected, the landing gear downlock pins were fitted. However, when the lead engineer selected the landing gear lever to up, the NLG retracted.

The aircraft’s nose struck the ground causing significant damage to the lower front section of the aircraft and inflicting minor injuries on the co-pilot and one of the cargo loading team.

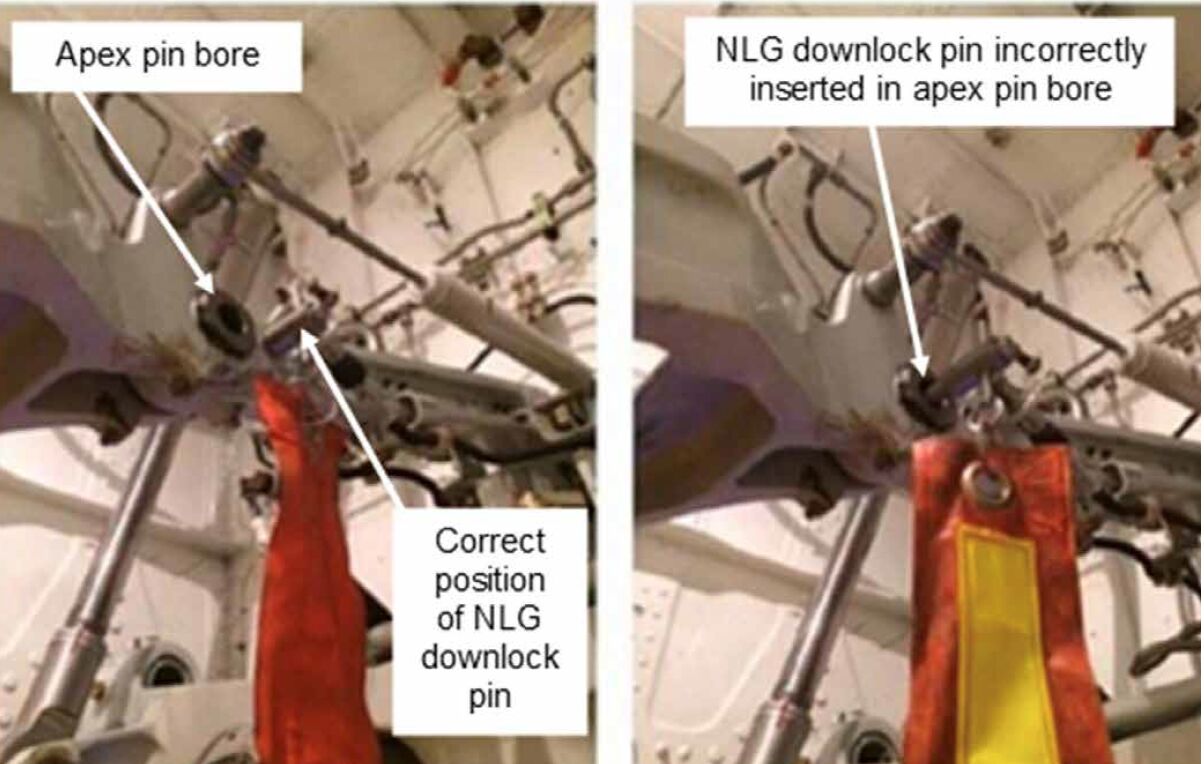

The NLG downlock pin had inadvertently been inserted in the downlock link assembly apex pin bore instead of the downlock pin hole.

The design of the aircraft nose landing gear downlock assembly created an opportunity for error when inserting the NLG locking pin, with two holes located so close together that the pin could be inadvertently inserted in the incorrect location.

Boeing's Illustration of Location of apex pin bore and the downlock pin hole.

A Service Bulletin and Airworthiness Directive was available that would have prevented the accident, but this had not yet been completed on G-ZBJB.

The operator and the airport have introduced a number of Safety Actions which cover the adoption of corrective modifications to the aircraft, changes to maintenance and incident response procedures.

The aircraft was scheduled to operate a freighter flight from London Heathrow Airport to Frankfurt Airport. The aircraft was planned to be operated by two pilots accompanied by an Overseas Engineer (OSE) to provide technical support down route.

The pilots arrived at the operator’s Crew Reporting Centre at approximately 0520 hrs and collected the flight briefing pack. The pilots met the OSE prior to briefing but he had some engineering matters to attend to, so did not attend the flight crew briefing. The briefing pack referred to an outstanding technical issue with the aircraft related to the NLG door solenoids.

The pilots consulted the relevant Minimum Equipment List entry and confirmed that the defect caused no operational or aircraft performance issues. The rest of the briefing was routine and the crew went through security and reunited with the OSE at the crew bus gate at approximately 0620 hrs.

The aircraft was parked on a remote stand and the crew arrived at the aircraft at approximately 0625 hrs. Three ground engineering personnel were on the flight deck when the pilots and the OSE arrived.

They informed the crew that they were attempting to resolve a number of Engine Indicating and Crew Alert System (EICAS) status messages related to the NLG door solenoids. The OSE offered his assistance to the ground personnel in dealing with the issues but was told he was not required.

The OSE left the flight deck to perform his pre‑departure checks of the cabin. The commander asked the Licensed Aircraft Engineer (LAE) for an estimated timeframe for rectification of the issues and was told it would take around 40 minutes.

The commander then left to conduct the aircraft walk around checks. During the walk around checks the commander did not recall seeing any landing gear locking pins installed. Two of the ground engineers left the flight deck and the LAE remained in the left seat working through the engineering procedures on a laptop.

The co-pilot sat in the right seat and began his pre-departure checks. The co-pilot had limited interaction with the LAE as he was focused on his own task. He did recall that the engineer pressurised a hydraulic system.

The co-pilot received the flight departure clearance by datalink at 0650 and very shortly after that recalled the LAE raising the gear lever to up. The co-pilot recalled hearing the gear system actuate and then the aircraft nose struck the ground.

Though the co-pilot sustained a minor injury the engineer was unhurt. Following the NLG retraction, the co-pilot recalled that alternating current (AC) electrical power had been lost and that the Auxiliary Power Unit (APU) had shut down. The co-pilot then moved the APU selector to shut off but left the aircraft battery on to facilitate RTF communications. He did not make a RTF call to inform ATC of the incident.

By 2018 there had been two incidents reported to Boeing of B787 NLG retractions on the ground with weight on wheels because the NLG downlock pin had accidentally been fitted to the apex pin bore when landing gear up was selected.

The second occurrence was at the Boeing facility in March 2018. The manufacturer initially raised a Service Related Problem (SRP) to investigate the NLG downlock pin problem and to identify corrective action followed by a Service Bulletin.

AAIB conducts an excess of 200 investigations by correspondence each year . These scope of investigations can vary in the level of detail, depending on the nature of the accident/Incident.

A report of an accident to a light aircraft , with no fatal or life-threatening injuries to the pilot or passengers, may be completed following a brief questionnaire answered by the pilot.

However , a correspondence investigation into a serious Incident / Accident involving a commercial aircraft can include the recovery of flight data recorders and analysis of evidence in the AAIB's laboratories.

Courtesy : AAIB Bulletin : AAIB-27411