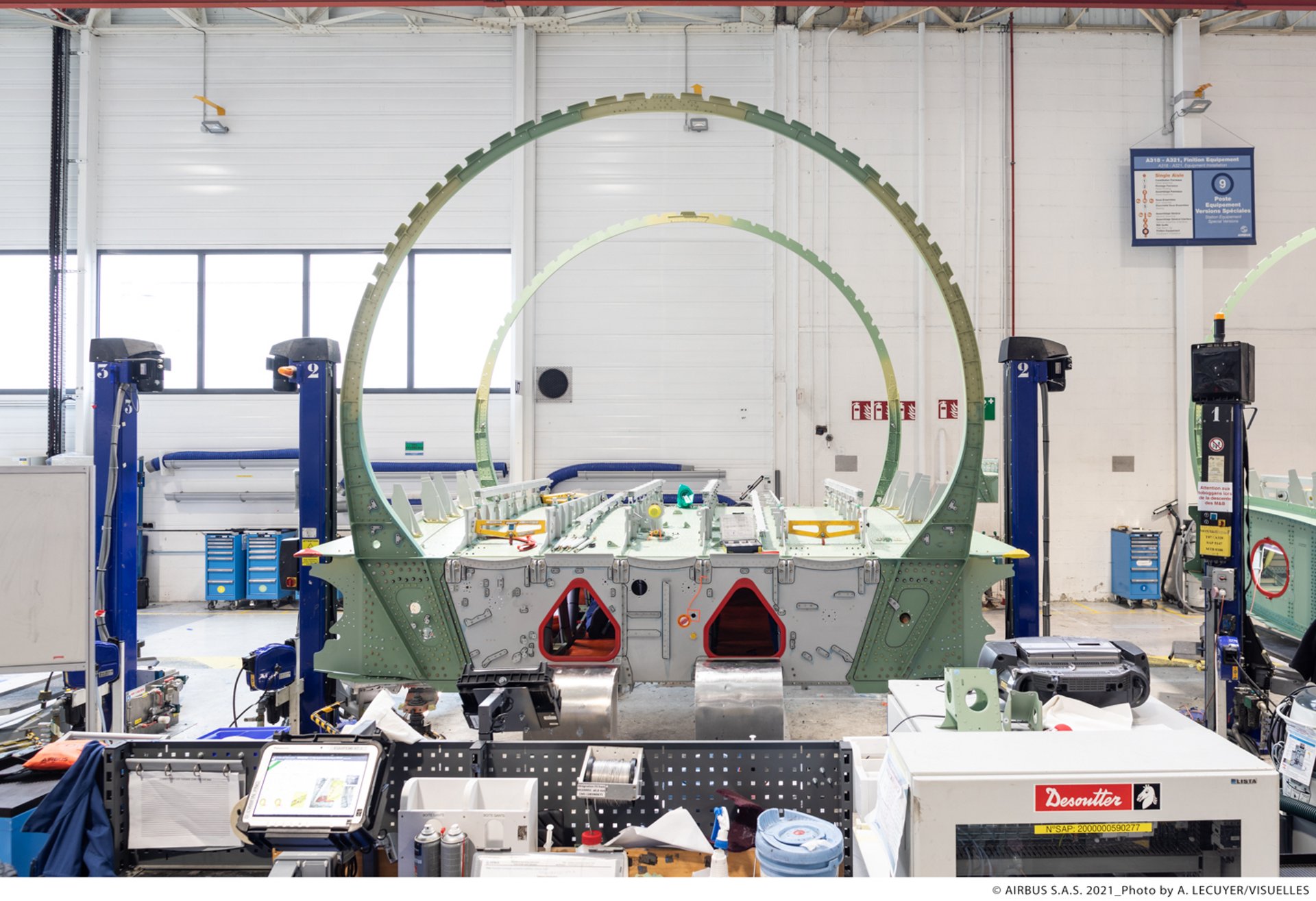

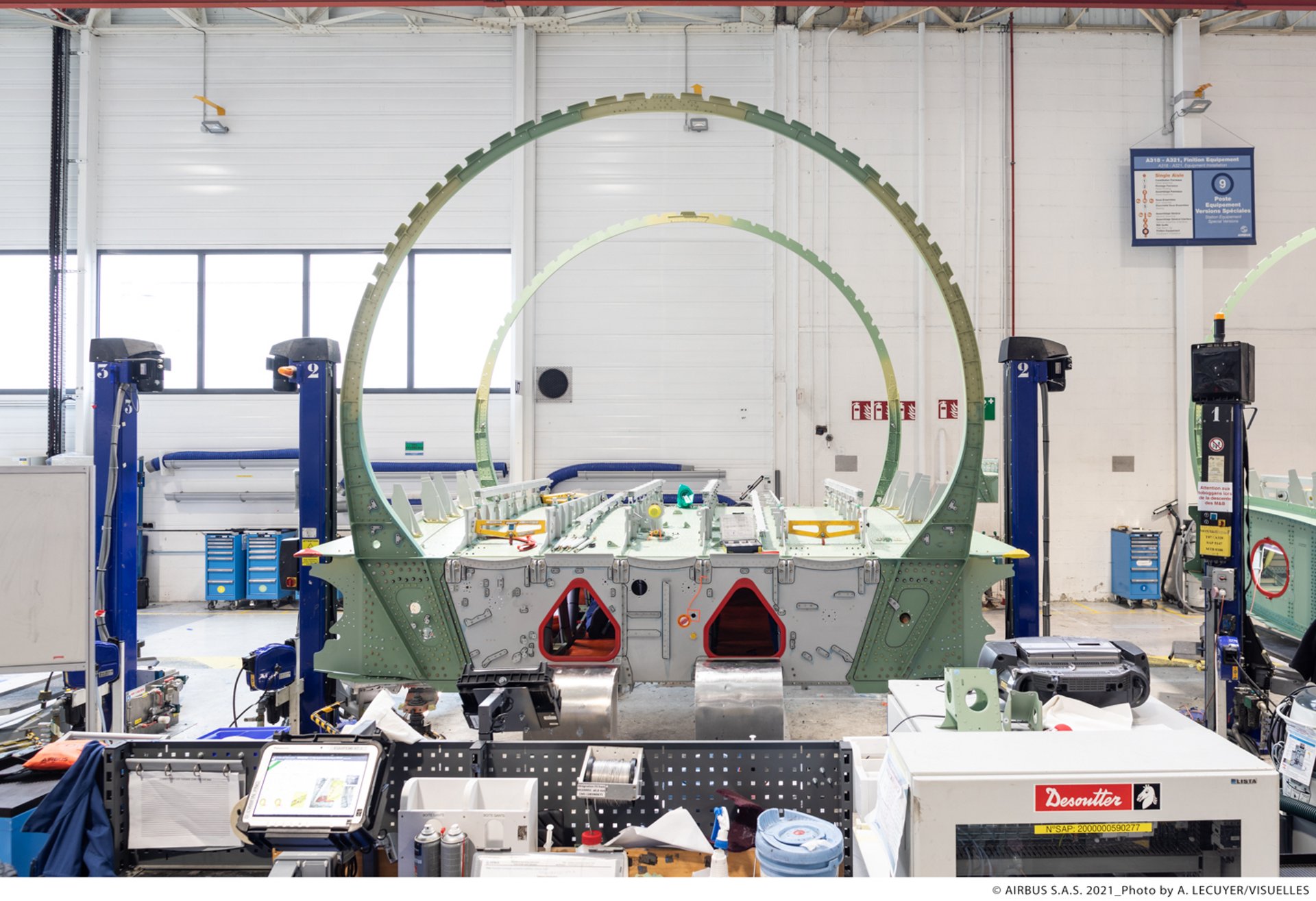

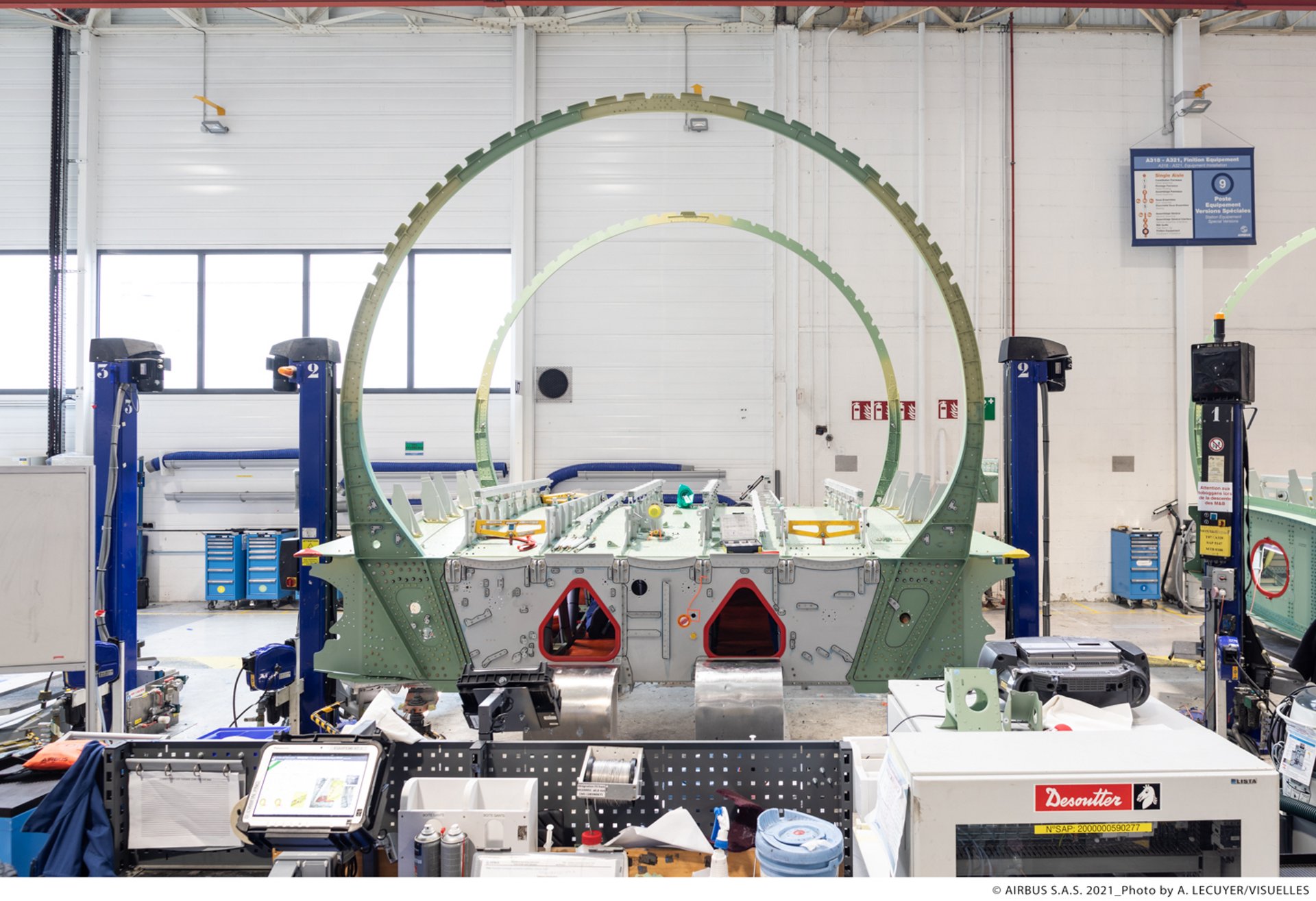

On Monday, airbus announced that, it has delivered one of the important Structural assembly - the Centre Wing Box (CWB) of the Upcoming Airbus A321 XLR to Hamburg.

"Airbus teams have reached an important milestone in the production of the A321XLR with the delivery to Hamburg of the first centre wing box."

Airbus teams in Nantes, France, delivered the very first A321XLR’s Centre Wing Box (CWB), 16 months after machining the first metal cuts.

This is an important moment for the Nantes teams and for the programme, as the CWB is one of the first major components delivered to the Hamburg integrator site for the start of structural assembly activities for the center fuselage known as “Section 15” in the A320 Family.

Challenge was enormous, as they were going to modify a Legacy aircraft's (read as A320 family) Centre wing Box (CWB) to achieve something unseen.

At a very early stage in the Airbus production cycle, the CWB - the structural heart of the aircraft and a speciality of the Nantes site - represents a significant challenge in terms of planning execution:

“The CWB is always the first major component on each new aircraft development to be produced so we must mature its design very early and manage its interdependencies with fuel systems, load calculations, as well as physical interfaces to the airframe aerostructure components developed in France, Germany and the UK,” explain Yannick Valette, Integrated Product Team Nose & Forward Fuselage (IPT NFF) A321XLR Programme Leader, and Richard Hue, CWB Project Leader.

Nantes team did an additional 200 plus modifications to the New CWB , that will support the increased maximum take-off weight (MTOW) capability of the A321XLR, parts of the CWB also got reinforced, such as the spars, frames and upper and lower panels.

Fuel system components have also been added to the CWB to allow the supply of fuel to the new Rear Centre Tank (RCT) integrated into the fuselage in Hamburg, which provides the A321XLR with an increased fuel capacity of around 12,900 litres, giving a total maximum capacity of 40,000 litres on the aircraft.

Now Hamburg will develop the centre Fuselage of the Upcoming A321XLR . CWB was Delivered by a Beluga to the Hamburg site.

The CWB will be integrated together with Section 15 (the RCT Flange-Module) into the front part of the Center-Aft-Fuselage (CAF), hereby launching the start of assembly for the main components of this first aircraft in the dedicated H260 “Structure Pilot Line” in Hamburg.

Meanwhile, in Nantes, the next two CWBs, which are intended for the flight test aircraft, are already being assembled.

Looking further ahead, the CWB for the first customer-delivered aircraft is planned to enter production in Q4 2021.

Picture Source : Airbus.