Aircrfat Technical facts - How do Aircraft Mechanics do the inaccessible area 'hole reaming' on the aircraft structures without a power tool ?

Generally Done in an MRO ( Maintenance Repair & Overhaul) facility , Reaming is a process of making precision adjustments ( mostly in increments of 0.001 inches) to the dimensions of a hole drilled on a structure.

Most of the reaming work on aircrafts are done using a power tool like a 'Drill gun' attached with a 'Reamer' at the work end .

Sometimes, when there is no access to the hole to be reamed, the reaming process is done using a hand tool , suiting to the location of the hole.

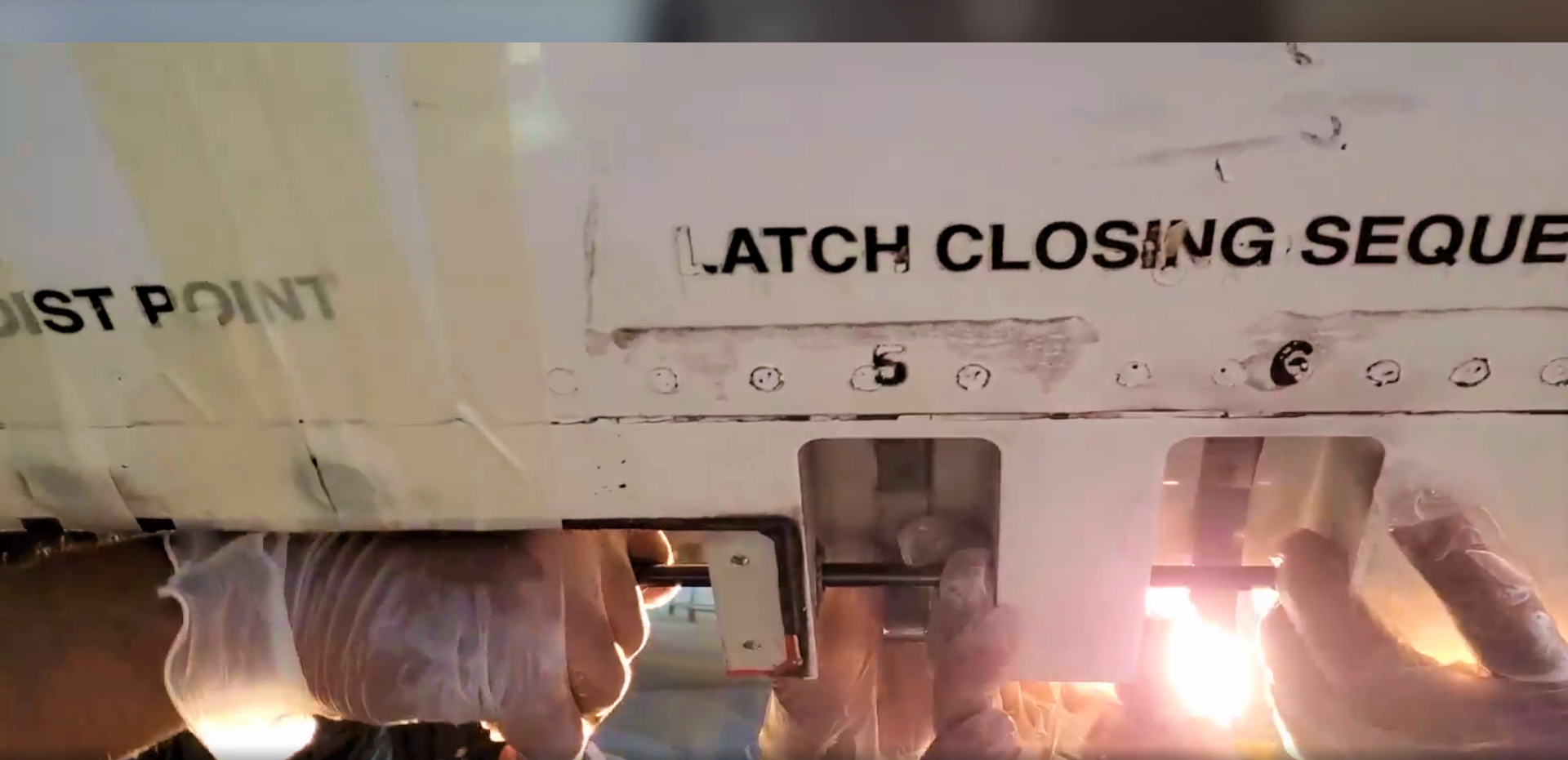

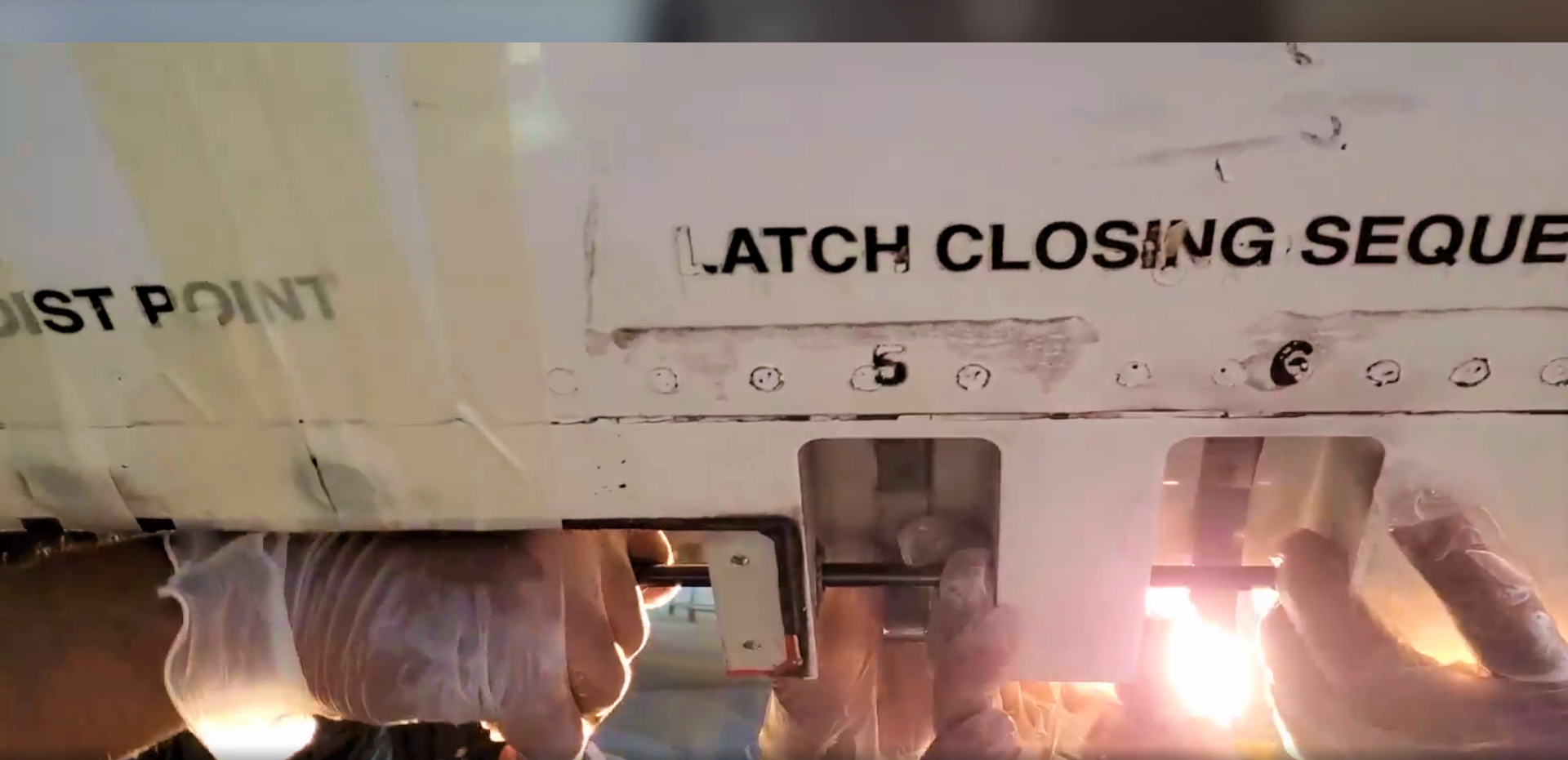

In this case, An Airbus A330 aircraft Left engine Outboard Thrust Reverser Cowl repair work is under progress.